BS 1414: Steel wedge gate valves for the petroleum, petrochemical and allied industries

1 - Scope

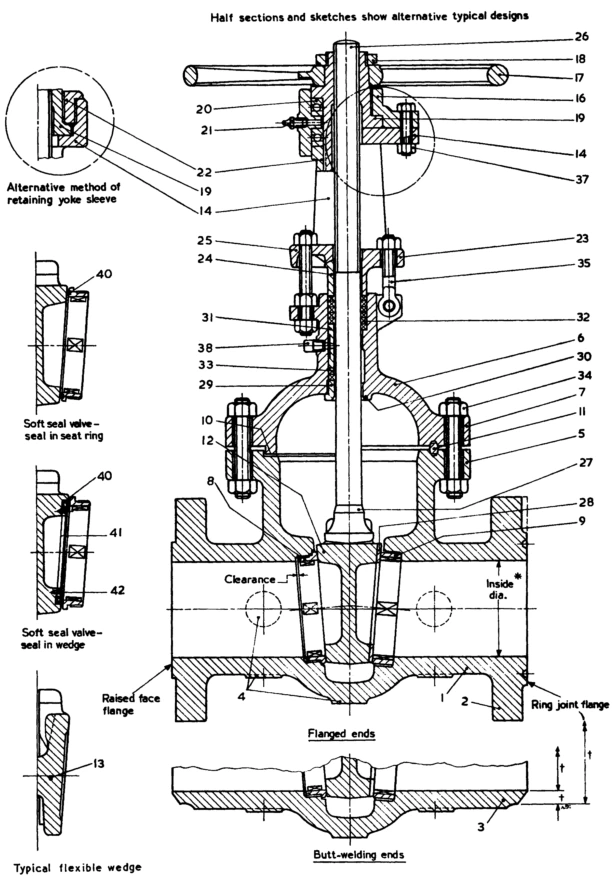

BS 1414 Standard specifies requirements for cast or forged carbon and alloy steel outside screw and yoke, solid wedge (plain or flexible) rising stem gate valves, with or without soft seals, with flanged or butt-welding ends, in nominal sizes within the range of 25 mm to 600 mm (1 in to 24 in) and Class 150 to Class 2 500.

BS 1414 also covers carbon steel valves in nominal sizes 650 mm to 1 050 mm (26 in to 42 in) in Class 150 and Class 300 only. This standard can also be used as a general guide where valves of material composition outside the scope of section three of this standard are required as, for example, for use in highly corrosive services or environments or for low temperatures (see clause 36).

4 - Pressure classification

This standard applies to valves of the following pressure class designations:

Class 150, Class 300, Class 400, Class 600, Class 900, Class 1 500 and Class 2 500.

The numerals in these class designations represent the primary service pressure ratings of the valves in pounds-force per square inch.

5 - Pressure/temperature ratings

The pressure/temperature ratings applicable to valves specified in this standard shall be in accordance with Tables PE-1 to PE-12 of Appendix A of BS 1560-2:1970 for the particular shell material specified. There is, however, a temperature restriction on soft seals and on certain trim materials (see 18.3 and 29.5).

Where valves in accordance with this standard are to be used at service temperatures below p 30 °C, reference should be made to BS 3351. Service temperature refers to the temperature of the fluid in the line at the valve.

6 - Nominal sizes

This standard covers valves of the following nominal sizes:

| mm | inch | mm | inch | mm | inch |

| 25 | 1 | 150 | 6 | 500 | 20 |

| 32 | 1-1/4 | 200 | 8 | 600 | 24 |

| 40 | 1-1/2 | 250 | 10 | 650 | 26 |

| 50 | 2 | 300 | 12 | 700 | 28 |

| 65 | 2-1/2 | 350 | 14 | 750 | 30 |

| 80 | 3 | 400 | 16 | 900 | 36 |

| 100 | 4 | 450 | 18 | 1050 | 42 |

a These sizes have been retained only for the purpose of replacing existing valves. Their use for new construction in piping systems using BS 1560-2 end flanges should be avoided.

For each valve class the applicable sizes are shown in Appendix A.

Figure 1 — Solid wedge gate valve, outside screw and yoke rising stem, cast or forged steel

43 - Production pressure testing

All valves shall be pressure tested by the manufacturer before despatch in accordance with BS 6755-1 as follows:

a) hydrostatic shell and backseat tests;

b) hydrostatic seat test (see note);

c) pneumatic seat test (see note).

The test durations shall be as given in Table 2a.

NOTE - Attention is drawn to note of D.8.3.2 of BS 6755-1:1986 regarding the sequence of operations when the seat test procedure is carried out. Valves tested to BS 1414 should have the sequence of items b) and c) in D.8.3.2 of BS 6755-1:1986 reversed. Seat test leakage rate A should apply. For the backseat test there should be no visual leakage for the duration of the test time.

Table 2a — Test durations

Related Standard:

API 600: Steel Gate Valves-Flanged and Butt-welding Ends, Bolted Bonnets