API 6D Ball Valve

Relia is a API 6D ball valve manufacturer with API 6D certificate, supplying API 6D floating ball valve and trunnion mounted ball valves.

API 6D ball valves are fully in compliance with the requirements for the the design,manufacturing, assembly, testing, and documentation of API 6D specifications.

- Valve Type

- Floating/Trunnion Ball Valve

- Standard

- API 6D

- Size

- 2"-48"

- Pressure Rating

- Class 150-2500

- Unit Price

- $50-20000

- Certificate

- API 6D

1. General Structure and Operation

- Spherical Closure Member: Ball valves in API 6D have a solid one-piece spherical closure member (ball) that rotates on an axis perpendicular to the direction of flow.

- Rotation Mechanism: The ball is designed to rotate within the valve body to control the flow. When the ball's bore is aligned with the flow path, fluid flows freely; when perpendicular, flow is blocked.

- Fire-safe Design: Fire-safe design to meet API 6FA or API 607 standards.

- Anti-static Device: Ball valves shall have electrical resistance not to exceed 10Ω.

- Cavity Pressure Relief: If liquid or multi-phase fluid trapping is possible, the valve will be provided with automatic cavity-pressure relief. For design temperature up to 250 °F (121 °C) the valve cavity relief shall not exceed 33% differential pressure above the valve pressure rating.

- Locking Device: Can be provided to lock the valve in the open or closed position.

- Position Indicator: Visual or mechanical indicator to show the position of the ball (open or closed).

- Extended Stem: For below-ground applications, an extended stem with a protective housing is available.

2. End Connections

- Flanged and Welding Ends: Ball valves covered by API 6D are available with flanged or welding ends to suit different piping systems and application requirements.

3. Sealing and Seat Design

- Seat Types: Ball valves can be equipped with single or double seats, depending on the sealing requirements.

- Bidirectional or Unidirectional: The valve can be designed for bidirectional or unidirectional flow.

- Seal Materials: A variety of seal materials are available, including soft seats and metal-to-metal seats, to suit different media and operating conditions.

4. Pressure and Temperature Ratings

- Pressure Rating: API 6D Ball valves conform to ASME B16.34 pressure rating standards, with classes ranging from 150 to 2500.

- Temperature Rating: The valves are designed to operate within a specified temperature range, with materials selected to maintain performance across this range.

5. Materials of Construction

- Body and Closure Member: Commonly made from cast or forged steel, with options for stainless steel, alloy steel, and other corrosion-resistant materials.

- Internal Components: Seats, stems, and other internal components are also made from materials suitable for the intended service conditions.

6. Testing and Validation

- Hydrostatic Shell Test: Performed to ensure the structural integrity of the valve body and end connections.

- Seat Tightness Test: Verifies the sealing capability of the ball and seat under specified pressure and temperature conditions.

- Additional Testing: Depending on the application, valves may undergo additional testing such as fire testing, low-temperature testing, and cavity relief testing.

7. Marking and Documentation

- Valve Marking: Each valve is marked with information including valve type, size, pressure class, material, and manufacturer details.

- Certification and Documentation: Provided with a certificate of conformance, material test reports, and pressure test reports as required by the specification.

API 6D Ball valves shall be of solid one-piece spherical construction with a closure member that rotates on an axis perpendicular to the direction of flow.

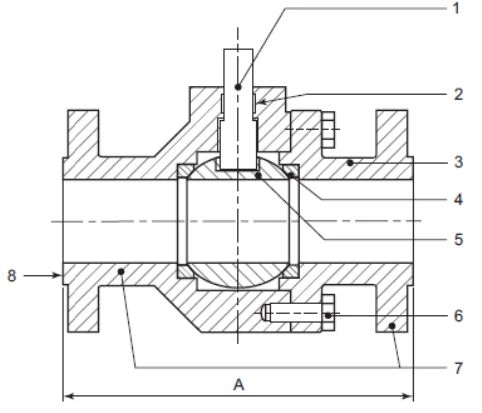

Typical configurations for API 6D ball valves with flanged or welding ends are shown, in Figure B.2, Figure B.3, Figure B.4, and Figure B.5.

Figure B.2-API 6D Floating Ball Valve

Assembly Drawing

Main Part

| Part No. | Part Name |

| 1 | stem |

| 2 | stem seal |

| 3 | end connector |

| 4 | seat ring |

| 5 | ball |

| 6 | body bolting |

| 7 | raised face |

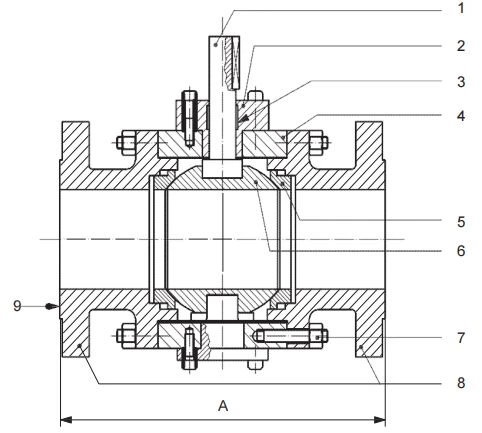

Figure B.3-API 6D Trunnion Mounted Ball Valve (Side Entry )

Assembly Drawing

Main Part

| Part No. | Part Name |

| 1 | stem |

| 2 | body cover |

| 3 | stem seal |

| 4 | body |

| 5 | seat ring |

| 6 | ball |

| 7 | body bolting |

| 8 | end connector |

| 9 | raised face |

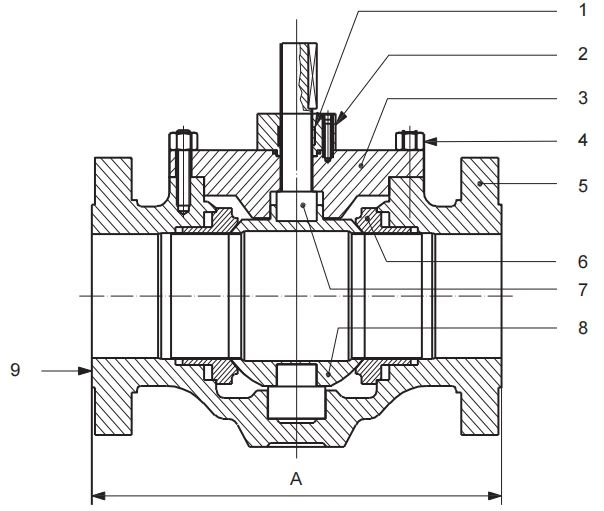

Figure B.3-API 6D Trunnion Mounted Ball Valve (Top Entry )

Assembly Drawing

Main Part

| Part No. | Part Name |

| 1 | stem seal |

| 2 | body cover |

| 3 | bonnet |

| 4 | body bolting |

| 5 | body |

| 6 | seat ring |

| 7 | stem |

| 8 | ball |

| 9 | raised face |

API 6D specification defines the requirements for the design,manufacturing, materials, welding, quality control,assembly,testing, marking,documentation and process controls of axial, ball,check,gate,plug valves for application in the petroleum and natural gas industries.

Valve Bore

Full-opening Valves

Full-opening valves shall be unobstructed in the fully opened position and shall have an internal minimum circular opening for categorizing bore size as specified in Table 1. When pipe is used in the construction of the valves, the pipe shall meet the tolerances of the applicable pipe specification. Closure member and seat dimensions shall meet Table 1.

Valves with a noncircular opening through the closure member shall not be identified as full opening.

Reduced-opening Valves with Circular Opening

Reduced-opening valves with a circular opening through the closure member shall be supplied with a minimum bore as follows:

― valves NPS 4 (DN 100) to NPS 12 (DN 300): one size below nominal size of valve with bore according to Table 1,

― valves NPS 14 (DN 350) to NPS 24 (DN 600): one or two sizes below nominal size of valve with bore according to Table 1.

― valves sizes less than NPS 4 (DN 100) or greater than NPS 24 (DN 600) in conformance with K.3

EXAMPLE An NPS 16 (DN 400) Class 1500 reduced-opening ball valve has an allowable minimum bore of 11.30 in.(287.0 mm).

Table 1—Minimum Bore for Full-opening Valves

| NPS | DN | Minimum a Bore by Class, in. (mm)b | |||

| Class 150 to 600 | Class 900 | Class 1500 | Class 2500 | ||

| ½ | 15 | 0.50 (12.7) | 0.50 (12.7) | 0.50 (12.7) | 0.50 (12.7) |

| ¾ | 20 | 0.75 (19.0) | 0.75 (19.0) | 0.75 (19.0) | 0.75 (19.0) |

| 1 | 25 | 0.98 (25.0) | 0.98 (25.0) | 0.98 (25.0) | 0.98 (25.0) |

| 1¼ | 32 | 1.25 (31.8) | 1.25 (31.8) | 1.25 (31.8) | 1.25 (31.8) |

| 1½ | 40 | 1.50 (38.0) | 1.50 (38.0) | 1.50 (38.0) | 1.50 (38.0) |

| 2 | 50 | 1.93 (49.0) | 1.93 (49.0) | 1.93 (49.0) | 1.65 (42.0) |

| 2½ | 65 | 2.44 (62.0) | 2.44 (62.0) | 2.44 (62.0) | 2.05 (52.0) |

| 3 | 80 | 2.91 (74.0) | 2.91 (74.0) | 2.91 (74.0) | 2.44 (62.0) |

| 4 | 100 | 3.94 (100.0) | 3.94 (100.0) | 3.94 (100.0) | 3.42 (87.0) |

| 6 | 150 | 5.91 (150.0) | 5.91 (150.0) | 5.67 (144.0) | 5.16 (131.0) |

| 8 | 200 | 7.91 (201.0) | 7.91 (201.0) | 7.55 (192.0) | 7.04 (179.0) |

| 10 | 250 | 9.92 (252.0) | 9.92 (252.0) | 9.41 (239.0) | 8.78 (223.0) |

| 12 | 300 | 11.93 (303.0) | 11.93 (303.0) | 11.30 (287.0) | 10.43 (265.0) |

| 14 | 350 | 13.15 (334.0) | 12.67 (322.0) | 12.40 (315.0) | 11.50 (292.0) |

| 16 | 400 | 15.16 (385.0) | 14.69 (373.0) | 14.17 (360.0) | 13.11 (333.0) |

| 18 | 450 | 17.16 (436.0) | 16.65 (423.0) | 15.98 (406.0) | 14.72 (374.0) |

| 20 | 500 | 19.17 (487.0) | 18.54 (471.0) | 17.87 (454.0) | 16.50 (419.0) |

| 22 | 550 | 21.18 (538.0) | 20.55 (522.0) | 19.69 (500.0) | — |

| 24 | 600 | 23.19 (589.0) | 22.44 (570.0) | 21.50 (546.0) | — |

| 26 | 650 | 24.92 (633.0) | 24.29 (617.0) | 23.38 (594.0) | — |

| 28 | 700 | 26.93 (684.0) | 26.18 (665.0) | 25.23 (641.0) | — |

| 30 | 750 | 28.94 (735.0) | 28.03 (712.0) | 27.00 (686.0) | — |

| 32 | 800 | 30.66 (779.0) | 29.92 (760.0) | 28.74 (730.0) | — |

| 34 | 850 | 32.68 (830.0) | 31.81 (808.0) | 30.50 (775.0) | — |

| 36 | 900 | 34.41 (874.0) | 33.66 (855.0) | 32.24 (819.0) | — |

| 38 | 950 | 36.42 (925.0) | 35.59 (904.0) | — | — |

| 40 | 1000 | 38.43 (976.0) | 37.63 (955.8) | — | — |

| 42 | 1050 | 40.16 (1020.0) | 39.61 (1006.0) | — | — |

| 48 | 1200 | 45.90 (1166.0) | 45.24 (1149.0) | — | — |

| 54 | 1350 | 51.65 (1312.0) | — | — | — |

| 56 | 1400 | 53.54 (1360.0) | — | — | — |

| 60 | 1500 | 57.40 (1458.0) | — | — | — |

| FOOTNOTES a There is no upper size limit for a valve bore. b The millimeter dimension is the inch dimension multiplied by 25.4 and rounded to one decimal place. “—“ = No identified minimum bore. | |||||

Pressure and Temperature Rating

Pressure–temperature ratings for class-rated valves shall conform to the rating table for the applicable material group per ASME B16.34 or for carbon steel per MSS-SP 44.

The pressure–temperature rating applied shall be based on the material group of the valve end connector. Where the valve ends are made from material in two different groups, the material with the lower pressure–temperature rating shall determine the rating.

NOTE Different material or material forms may be used for body and bonnet or cover parts within the same valve.

All metallic pressure-containing and pressure-controlling parts shall be designed to meet the identified valve pressure–temperature rating.

The manufacturer shall determine any limits on the maximum allowable operating pressure and shall identify theminimum and maximum design temperatures resulting from the nonmetallic parts used.

Pressure Testing Procedure

Written test procedures that identify test methodology, test durations and acceptance criteria shall be developed and maintained for all pressure testing performed in conformance to this specification.

Each valve shall be tested in the fully assembled condition to the manufacture’s procedures prior to shipment. Pressure testing shall be carried out before external coating of the valve.

NOTE If the valve has been previously pressure tested to the requirements of this specification, subsequent repeat hydrostatic and gas testing may be performed without removal of the valve external coating.

Testing shall be performed in the sequence as listed in order of 10.3 to 10.4.5. The backseat test that is only applicable to valves per 10.2 shall be performed either immediately before or immediately after the hydrostatic shell test in 10.3.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)