Forged Steel Check Valve

Forged steel check valves are also piston check valves and swing check valves. Forged steel check valves are made of forged material for the body and trim.

Features:

- Design: API 602 and ASME B16.34

- Disc types: piston, swing check, or ball check valve.

- Body-Cover Joint: bolted cover, pressure-sealed cover, or welded cover.

- Seat: integral weld overlay for piston and ball check valve; separated seat ring for swing check valve.

- Bore: full bore or reduced bore

Size

1/2" - 2"

Pressure Rating

Class 150 - 2500

End Connections

Flanged, Welded, Threaded

Body Material

Forged Carbon steel, stainless steel, alloy steel, duplex steel in forged type

Standard Specifications

| Design | ASME B16.34 - BS 5352 | Test | API 598 |

| Socket Weld | ASME B16.11 | Screw End | ASME B1.20.1 |

| Butt Weld Ends | ASME B16.25 | End Flanges | ASME B16.5 |

Forged Steel Check Valve Drawings

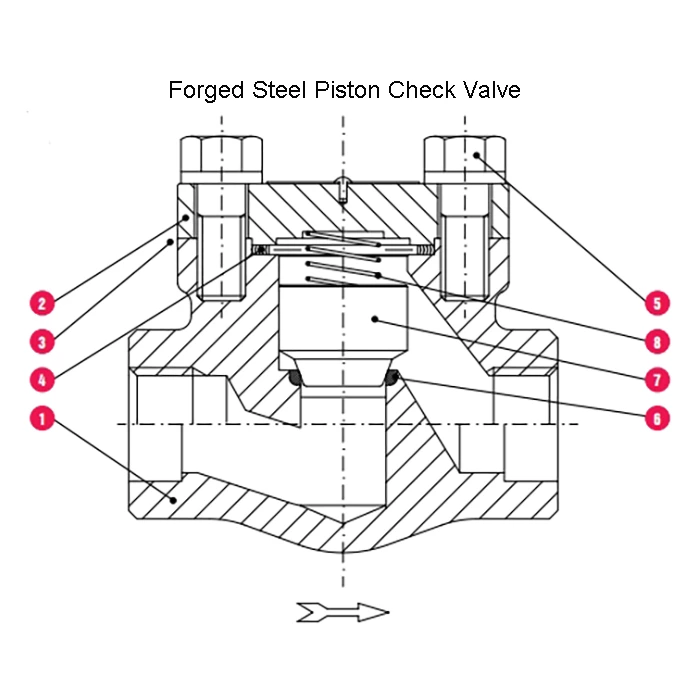

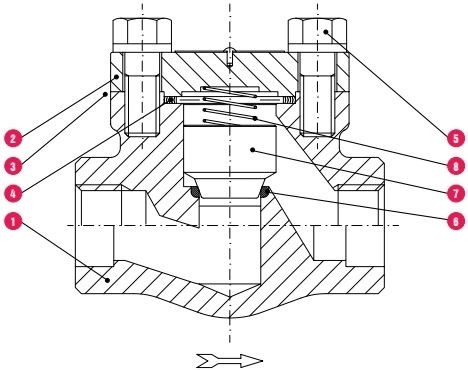

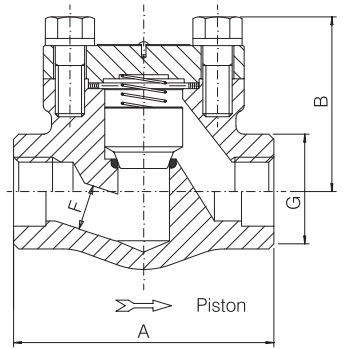

Forged steel piston check valve

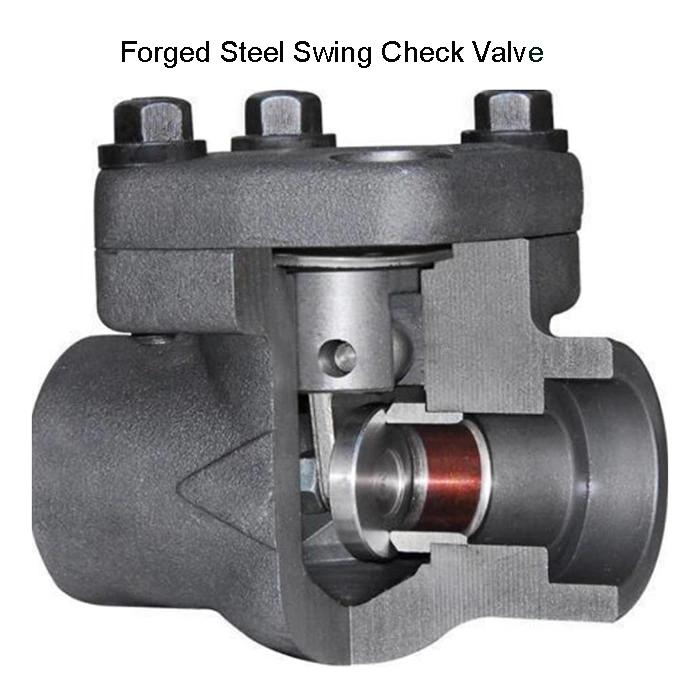

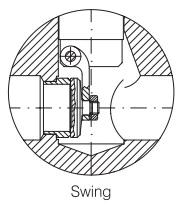

Forged steel swing check valve drawing

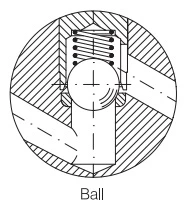

Forged steel ball check valve drawing

Material Specifications

| No. | Part Name | Material | ||||

| Forged Carbon Steel | Hight Temperature | Forged Stainless Steel | Sour Service | Low Temperature Forged Steel | ||

| 1 | Body | ASTM A105N | ASTM A182 F11/F22 | ASTM A182 F304 | ASTM A105 | ASTM A350 LF2 |

| 2 | Cover | ASTM A105N | ASTM A182 F11/F22 | ASTM A182 F304 | ASTM A105 | ASTM A350 LF2 |

| 4 | Gasket | 304SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 5 | Bolt | A193 B7 | A193 B16 | A193 B8 | A193 B7M | A320 L7M |

| 6 | Seat | STL Overlay | STL Overlay | STL Overlay | STL Overlay | STL Overlay |

| 7 | Disc | A182 F6a | A182 F6a | A182 F316 | A182 F6a Nace | A182 F316 |

| 8 | Spring | A276 316 | A276 316 | A276 316 | A276 316 | A276 316 |

Dimensions & Weight

Forged Steel Check Valve, Class 800, Full Port

| Size | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" |

| A (mm) | 80 | 80 | 90 | 110 | 127 | 150 | 180 | 210 |

| B (mm) | 55 | 55 | 60 | 78 | 88 | 92 | 108 | 145 |

| F, Piston Check Valve (mm) | 7 | 9 | 13 | 17.5 | 22.5 | 29.5 | 35 | 45 |

| F, Swing Check Valve (mm) | 8 | 9.6 | 14 | 18 | 24 | 30 | 36.6 | 48 |

| G (mm) | 32 | 32 | 38 | 48 | 56 | 64 | 78 | 85 |

| Weight (kg) | 1.4 | 1.4 | 1.6 | 3 | 4.3 | 5.6 | 10 | 16 |

Forged Steel Check Valve, Class 800, Reduced Port

| Size | 1/2" | 3/4" | 1" | 1-1/2" | 2" |

| A (mm) | 80 | 90 | 110 | 150 | 180 |

| B (mm) | 55 | 60 | 78 | 92 | 108 |

| F, Piston Check Valve (mm) | 9 | 13 | 17.5 | 29.5 | 35 |

| F, Swing Check Valve (mm) | 9.6 | 14 | 18 | 30 | 36.6 |

| G (mm) | 32 | 38 | 48 | 64 | 78 |

| Weight (kg) | 1.3 | 1.6 | 2.8 | 5.6 | 9 |

Forged Steel Check Valve, Class 1500, Full Port

| Size | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" |

| A (mm) | 90 | 90 | 110 | 127 | 150 | 180 | 210 | 210 |

| B (mm) | 60 | 60 | 78 | 88 | 92 | 108 | 145 | 150 |

| F, Piston Check Valve (mm) | 7 | 9 | 12 | 15 | 20 | 27 | 32 | 40 |

| F, Swing Check Valve (mm) | 14 | 18 | 24 | 30 | 36.6 | 48 | ||

| G (mm) | 38 | 38 | 48 | 56 | 64 | 78 | 85 | 95 |

| Weight (kg) | 1.7 | 1.7 | 3.1 | 4.6 | 6.5 | 10.6 | 19 | 19 |

Forged Steel Check Valve, Class 1500, Reduced Port

| Size | 1/2" | 3/4" | 1" | 1-1/2" | 2" |

| A (mm) | 90 | 110 | 127 | 180 | 210 |

| B (mm) | 60 | 78 | 88 | 108 | 145 |

| F, Piston Check Valve (mm) | 9 | 12 | 15 | 27 | 32 |

| F, Swing Check Valve (mm) | 9.6 | 14 | 18 | 30 | 36.6 |

| G (mm) | 38 | 48 | 56 | 78 | 85 |

| Weight (kg) | 1.7 | 3 | 4.4 | 10 | 18 |

Other Features:

GASKET - The bolted cover forged steel check valve uses a contained,controlled compression, spiral wound type gasket.

COVER BOLTING - The cover bolting is manufactured of alloy steel in accordance with the requirements of the applicable specifications such as API 602 and ASME B16.34.

SPRING - The spring is optional and supplied only upon request.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)