Double Block and Bleed In Ball Valves

The double block and bleed valve is abbreviated to DBB valve.

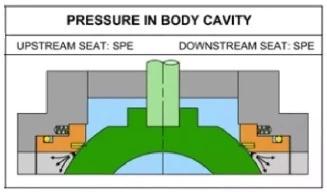

API 6D defines a double block and bleed valve as "a single valve with two seating surfaces that, in the closed position, provide a seal against pressure from both ends of the valve with a means of venting/bleeding the cavity between the seating surfaces."

There are a couple of different styles of double block and bleed valves. One style has two independently seating valves inside, with a bleed or drain valve.

Trunnion Ball Valve with DBB Function

Using a single double block and bleed valve saves installation time, weight on the piping system, and space. It also cuts down the number of leak paths to the atmosphere, reducing the risk of hazards when transferring liquids dangerous to humans or the environment.

Relia's trunnion ball valve combines double block and bleed into a single valve. This style can isolate piping on both sides of the valve (uni-directionally) to vent/bleed the valve cavity between the seats.

One-Valve Combination of Two Balls and Needle Valve

It is made up of two ordinary ball valves linked by a common inlet end. The double block and bleed ball valve is a product intended to substitute several connections between conventional valves; as the name suggests, it is a double block and bleed ball valve. The distinction between this DBB valve and the conventional one is that it can effectively overcome leakage that happens during system operation and it can be quickly closed and discharged easily.

Valve with two balls for block and one needle for bleeding

Valve with two balls for block and one needle for bleeding

DBB with twin trunnioin balls for block and one needle valve for bleeding

DBB with twin trunnioin balls for block and one needle valve for bleeding