Design Features

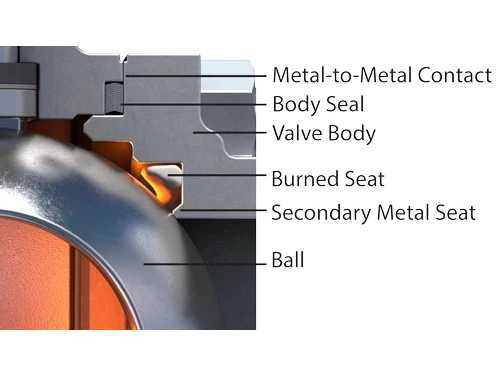

Fire Safe Design in Ball Valves

Fire safe ball Valves have the ability to maintain their pressure holding capacity during and after exposure to fire....

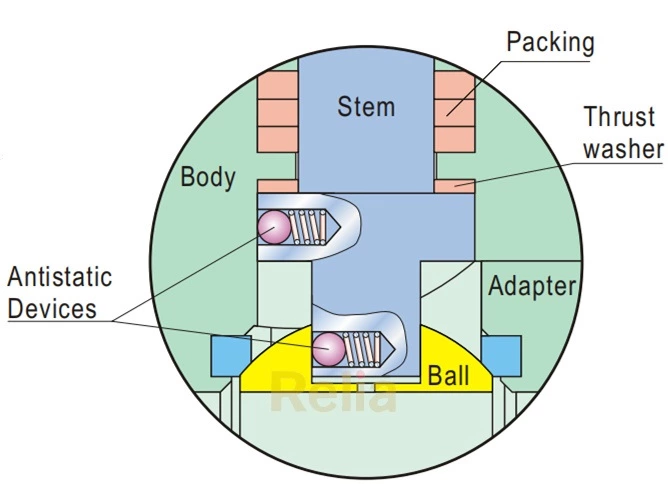

Anti-static Device In Ball Valves

An anti-static device used in a ball valve is to reduce the static charge generated on the ball due to friction. It is used to protect the valve against a spark that...

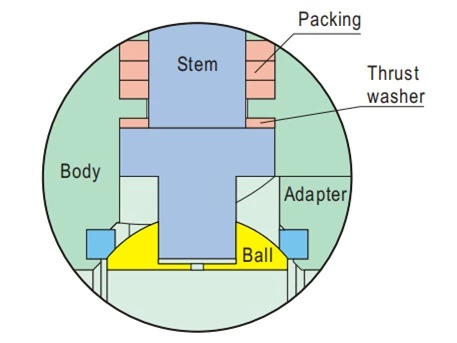

Anti-blow-out Stem in Ball Valves

Ball valves are designed with a stem anti-blow-out device to prevent stem ejection by internal pressure when the stem packing and/or retainer has been removed....

Double Block and Bleed In Ball Valves

Double block and bleed valves are single valves with two seating surfaces that, in the closed position, provide a seal against pressure from both ends of the valve with a...

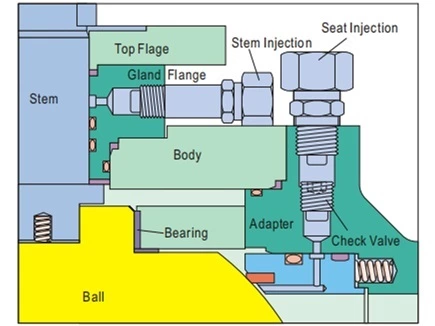

Emergency Sealant Injection In Ball Valves

The sealant injection provides a secondary and emergency seal to the stem and/or seat area of a ball valve by means of a suitable facility when soft sealing rings ar...

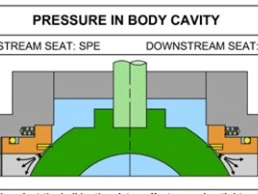

Automatic Body Cavity Relief In Ball Valves

Automatic cavity pressure relief is provided to relieve the trapped fluid into the internal pipeline, when the pressure of the trapped fluid goes up abnormally as the uns...