Floating Ball Valve

Relia is a floating ball valve manufacturer and supplier in China, providing cast and forged steel floating ball valves with fire safe, anti-static and locking designs at affordable price.

A floating ball valve is a ball valve with its ball floating inside the valve body. It drifts toward the downstream side and tightly pushes against the seat under the medium pressure to ensure sealing reliability. The Relia floating ball valve has a self-relieving seat that relieves pressure upstream.

The floating ball valve has a simple structure and good sealing performance, but the seat material is required to withstand the workload since the sealing pressure is borne by the seat ring.

- Standard

- API 6D/API 608/ISO 17292

- Size

- 1/2"-6"

- Pressure Rating

- Class 150-1500

- End Connections

- Flanged, Welded, Threaded

Standard Specifications

| Design and Manufacture | API 6D/API 608/BS5351/ISO 17292 | Face to Face Dimension | API 6D |

| Inspection and Testing | API 6D/API 598 | Wall Thickness | API 6D |

| Flange End Dimension | ANSI/ASME B16.5 | Material | Nace MR 0175 |

| Fire Safe Design | API 607/API 6FA |

Key Features

- Bi-directional seal, two-way

- Zero leakage

- Split body, side entry, 2 Pieces or 3 Pieces Body

- Fire safe

- Anti-static device

- Locking device

Key Material

Body Material

Carbon Steel, Stainless Steel, Low-Temperature Carbon Steel, Duplex, Super Duplex, Al Bronze, Inconel etc.

Seat Material

Soft Seat: PTFE, Nylon, PEEK, PPL, Delrin, Devlon etc.

Metal Seated: Stellite, Tunsten Carbide, Chrome Carbide

For selection of seat material, please refer to ball valve seat material selection guide

Ball Material

ENP, Stellite, Tunsten Carbide, Chrome Carbide

Operator

Manual: Lever, wrench or Gear

Actuated: Pneumatic/ Hydraulic/Electric

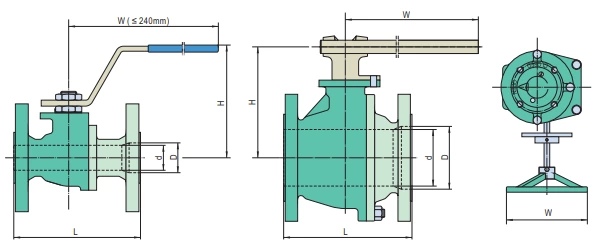

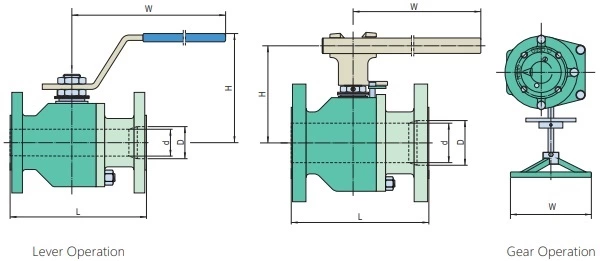

Typical Drawings

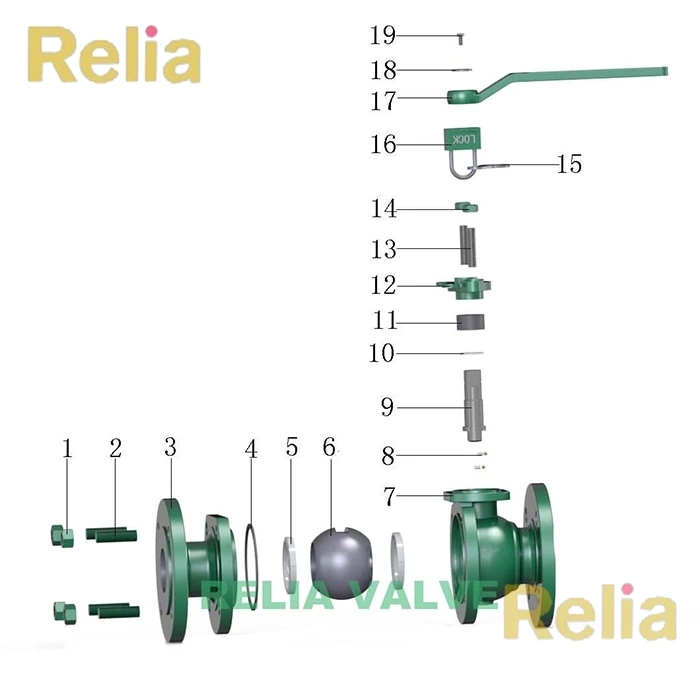

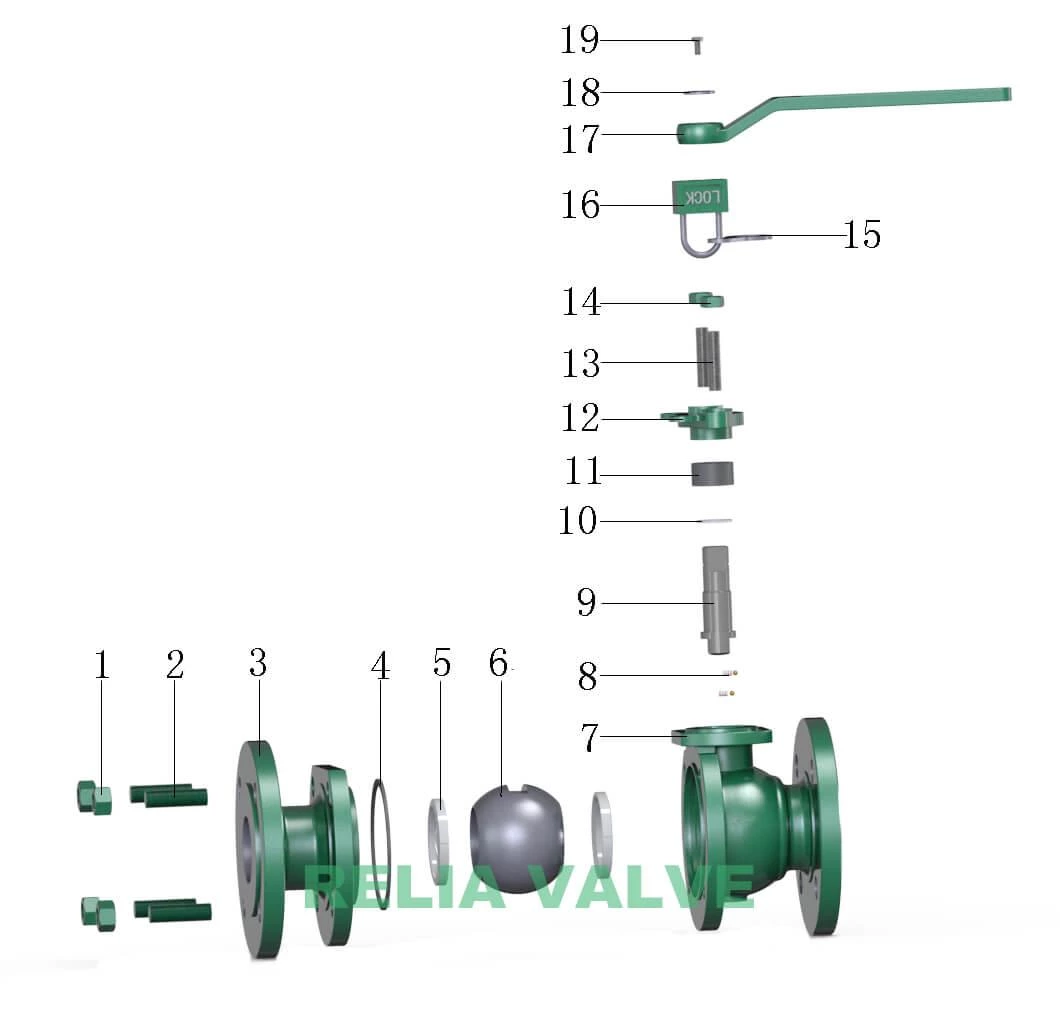

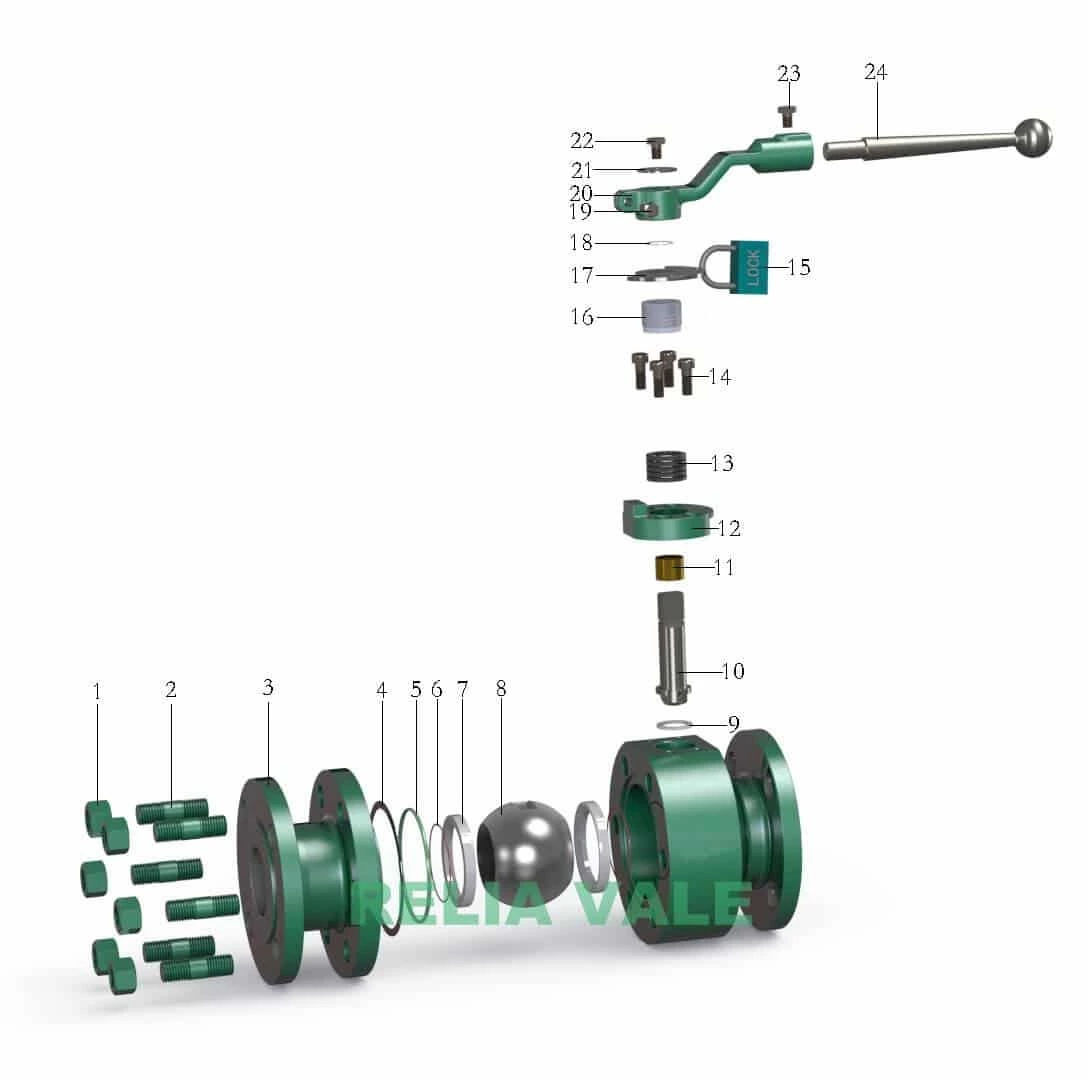

Cast Steel Flanged Floating Ball Valve

Material Specifications

| No. | Part Name | WCB/A105+ENP | LCB/F316 | A351 CF8M/F316 |

| 1 | Nut | ASTM A194 2H | ASTM A194 2HM | ASTM A194 8M |

| 2 | Bolt | ASTM A193 B7 | ASTM A193 B7M | ASTM A193 B8M |

| 3 | Bonnet | ASTM A216 WCB | ASTM A352 LCB | ASTM A351 CF8M |

| 4 | Gasket | SS304+Graphite | SS316+Graphite | SS316+Graphite |

| 5 | Seat | PTFE,RPTFE | PTFE,RPTFE | PTFE,RPTFE |

| 6 | Ball | ASTM A105+ENP | ASTM A182 F316 | ASTM A182 F316 |

| 7 | Body | ASTM A216 WCB | ASTM A352 LCB | ASTM A351 CF8M |

| 8 | Spring | SS 304 | SS 316 | SS 316 |

| 9 | Stem | A182 F6a | A182 F316 | A182 F316 |

| 10 | Thrust Washer | PTFE | PTFE | PTFE |

| 11 | Packing | Graphite | Graphite | Graphite |

| 12 | Packing Gland | ASTM A216 WCB | ASTM A352 LCB | ASTM A351 CF8M |

| 13 | Bolt | ASTM A193 B7 | ASTM A193 B7M | ASTM A193 B8M |

| 14 | Nut | ASTM A194 2H | ASTM A194 2HM | ASTM A194 8M |

| 15 | Hand Stop | Carbon Steel | Carbon Steel | Carbon Steel |

| 16 | Lock | Cast Iron | Cast Iron | Cast Iron |

| 17 | Lever | Carbon Steel | Carbon Steel | Carbon Steel |

| 18 | Gasket | Carbon Steel | Carbon Steel | Carbon Steel |

| 19 | Pin | Carbon Steel | Carbon Steel | Stainless Steel |

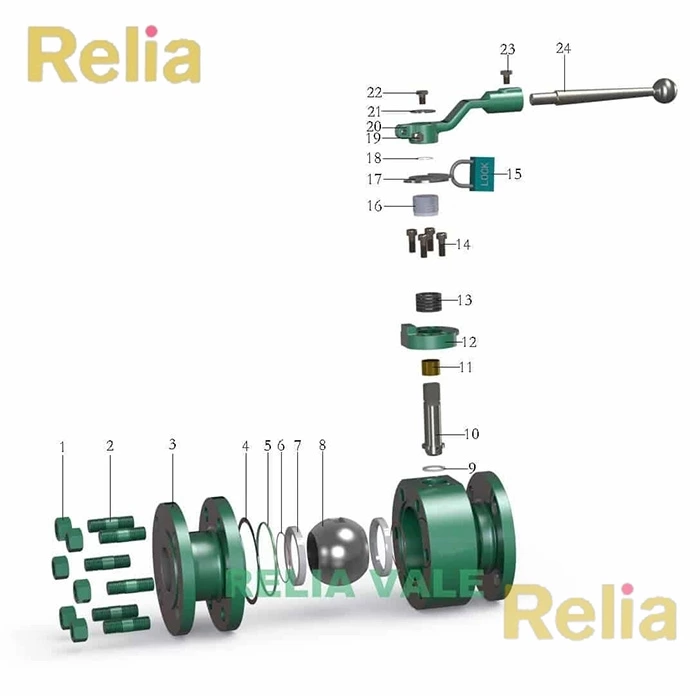

Forged Steel Flanged Floating Ball Valve

Material Specifications

| No. | Part Name | A105/A105+ENP | LF2/F316 | F316/F316 |

| 1 | Nut | A194 2H | A194 7M | A194 8M |

| 2 | Bolt | A193 B7 | A320 L7M | A193 B8M |

| 3 | Bonnet | ASTM A105 | ASTM A350 LF2 | ASTM A182 F316 |

| 4 | Gasket | 304+Graphite | 316+Graphite | 316+Graphite |

| 5 | O-Ring | Viton AED | Viton AED | Viton AED |

| 6 | O-Ring | Viton AED | Viton AED | Viton AED |

| 7 | Seat | PTFE | PTFE | PTFE |

| 8 | Ball | A105+ENP | A350 LF2+ENP | A182 F316 |

| 9 | Thrust Washer | PTFE | PTFE | PTFE |

| 10 | Stem | A182 F6a | A182 F316 | A182 F316 |

| 11 | Axle Sleeve | Stainless Steel | Stainless Steel | Stainless Steel |

| 12 | Stuffing Gland | ASTM A105 | ASTM A350 LF2 | A182 F316 |

| 13 | Packing | Graphite | Graphite | Graphite |

| 14 | Stud | A193 B7 | A320 L7M | A193 B8M |

| 15 | Lock | Cast Iron | Cast Iron | Cast Iron |

| 16 | Packing Gland | ASTM A105 | ASTM A350 LF2 | A182 F316 |

| 17 | Hand Stop | Carbon Steel | Carbon Steel | Carbon Steel |

| 18 | Snap Ring | Carbon Steel | Carbon Steel | Carbon Steel |

| 19 | Stud | A193 B7 | A320 L7M | A193 B8M |

| 20 | Handle | Carbon Steel | Carbon Steel | Carbon Steel |

| 21 | Gasket | SS304+Graphite | SS316+Graphite | SS316+Graphite |

| 22 | Stud | Carbon Steel | Carbon Steel | Carbon Steel |

| 23 | Sud | Carbon Steel | Carbon Steel | Carbon Steel |

| 24 | Lever | Carbon Steel | Carbon Steel | Carbon Steel |

Dimension and Weight

Note:

1. L - Face to face/end to end dimensions, d - minimum bore size

2. Face to face/end to end dimensions are according to ASME B16.10

Class 150 Floating Ball Valve Dimensions, Full Bore, Flanged Ends

| Size | d | L | H | W | Weight |

| Inch | mm | mm | mm | mm | Kg |

| 1/2 | 13 | 108 | 85 | 160 | 2 |

| 3/4 | 19 | 117 | 93 | 160 | 2 |

| 1 | 25 | 127 | 112 | 180 | 4 |

| 1-1/2 | 38 | 165 | 132 | 240 | 6 |

| 2 | 51 | 178 | 138 | 350 | 12 |

| 2-1/2 | 62 | 191 | 155 | 400 | 15 |

| 3 | 76 | 203 | 175 | 400 | 24 |

| 4 | 102 | 229 | 200 | 450 | 36 |

| 5 | 125 | 356 | 246 | 650 | 58 |

| 6 | 152 | 394 | 263 | *300 | 94 |

Class 300 Floating Ball Valve Dimensions, Full Bore

| Size | d | L | H | W | Weight |

| Inch | mm | mm | mm | mm | Kg |

| 1/2 | 13 | 140 | 85 | 160 | 2.5 |

| 3/4 | 19 | 152 | 93 | 160 | 4 |

| 1 | 25 | 165 | 112 | 180 | 5 |

| 1-1/2 | 38 | 190 | 132 | 240 | 10 |

| 2 | 51 | 216 | 138 | 400 | 13.5 |

| 2-1/2 | 62 | 241 | 155 | 400 | 21 |

| 3 | 76 | 283 | 175 | 450 | 30 |

| 4 | 102 | 305 | 200 | 500 | 50 |

| 5 | 125 | 381 | 246 | 550 | 65 |

| 6 | 152 | 403 | 263 | *300 | 122 |

Note: * means Gear operated floating ball valves.

Class 600 Floating Ball Valve Dimensions, Full Bore

| Size | d | L | H | W | Weight |

| Inch | mm | mm | mm | mm | Kg |

| 1/2 | 13 | 165 | 85 | 160 | 3.5 |

| 3/4 | 19 | 191 | 93 | 180 | 5.0 |

| 1 | 25 | 216 | 112 | 240 | 7.5 |

| 1-1/2 | 38 | 241 | 125 | 350 | 15 |

| 2 | 51 | 292 | 130 | 400 | 23 |

| 3 | 76 | 356 | 170 | * 500 | 48 |

| 4 | 102 | 432 | 216 | * 700 | 80 |

Note: * means Gear operated floating ball valves.

Class 900 Floating Ball Valve Dimensions, Full Bore

| Size | d | L | H | W | Weight |

| Inch | mm | mm | mm | mm | Kg |

| 1/2 | 13 | 216 | 85 | 160 | 5.0 |

| 3/4 | 19 | 229 | 93 | 180 | 8.0 |

| 1 | 25 | 254 | 115 | 240 | 10.0 |

| 1-1/2 | 38 | 305 | 128 | 400 | 20 |

| 2 | 51 | 368 | 148 | 450 | 25 |

| 3 | 76 | 381 | 196 | *600 | 50 |

Note: * means Gear operated floating ball valves.

Class 1500 Floating Ball Valve Dimensions, Full Bore

| Size | d | L | H | W | Weight |

| Inch | mm | mm | mm | mm | Kg |

| 1/2 | 13 | 216 | 85 | 160 | 5.0 |

| 3/4 | 19 | 229 | 112 | 180 | 8.0 |

| 1 | 25 | 254 | 115 | 240 | 10 |

| 1-1/2 | 38 | 305 | 123 | 400 | 20 |

| 2 | 51 | 368 | 132 | *450 | 30 |

Note: * means Gear operated floating ball valves.

Related Information

Valve body material selection guide

Ball valve seat material selection guide

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)