A352 LCB Ball Valve

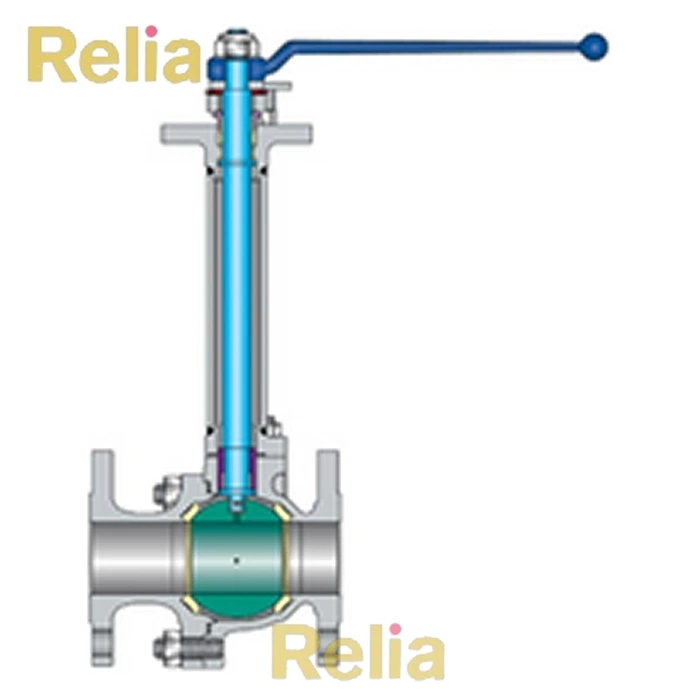

ASTM A352 LCB ball valves are intended primarily for low-temperature service at a minimum temperature of -46°C. Frequently, an extended bonnet is designed to avoid the valve stem seal contacting the low-temperature fluid.

A352 LCB are suitable for continuous service down to -46°C and up to 345°C.

More Products: A352 LCB Gate Valve, A352 Globe Valve, A352 Check Valve

A352 LCB Ball Valve Specifications

| Part Name | Body/Bonnet | Stem | Ball | Seat | Spring |

| Material | ASTM A352 LCB | A182 F316 | A182 F316 | RPTFE,Nylon,Devlon, PEEK, TCC, STL etc. |

Inconel 725 |

LCB Ball Valve Test Pressure

| Test Type | Test Fluid | Test Pressure (bar) | ||

| Class 150 | Class 300 | Class 600 | ||

| Shell Test | Water | 27.6 | 72.0 | 144.0 |

| High Pressure Seat Test | Water | 20.24 | 52.8 | 105.6 |

| Low Pressure Seat Test | Air | 6 | 6 | 6 |

A352 LCB Chemical Requirements

| A352 Code | UNS | Type | C | Mn | P | S | Si | Ni | Cr | Mo | Cu | V |

| LCB | J03003 | Carbon Steel | 0.30 | 1.00 | 0.04 | 0.045 | 0.06 | 0.50 | 0.50 | 0.20 | 0.30 | 0.03 |

Note:

A - All values are maximums unless a range is provided.

B- Where “. . .” appears in this table, there is no requirement, and the element need not be analyzed for or reported.

C- For each reduction of 0.01 % below the specified maximum carbon content, an increase of 0.04 % manganese above the specified maximum will be permitted up to a maximum of 1.10 % for LCA, 1.28 % for LCB, and 1.40 % for LCC.

D- Specified Residual Elements—The total content of these elements is 1.00 % maximum.

A352 LCB Mechanical Property Requirement

| A352 Code | UNS | Type | Tensile Requirements | Impact Requirements Charpy V-Notch | ||||||||||

| Tensile Strength, ksi [MPa | Yield Strength, C ksi [MPa] | Elongation in 2 in. [50 mm], % D | Reduction of Area, % | Minimum energy value for two specimens and minimum average of three specimens, ft·lbf [J] | Minimum energy value for single specimen, ft·lbf [J] | Testing Temperature, °F [°C] | ||||||||

| LCB | J03003 | Carbon Steel | 65.0-90.0 | 450-620 | 35.0 | 240 | 24 | 35 | 13 | 18 | 10 | 14 | -50 | -46 |

Note:

A- All values are minimums unless a range is provided.

B- See 1.2.

C- Determine by either 0.2 % offset method or 0.5 % extension-under-load method.

D- When ICI test bars are used in tensile testing as provided for in Specification A703/A703M, the gage length to reduced section diameter ratio shall be 4 to 1.

A352 LCB Working Pressure

| Temperature, °C | Working Pressures by Class, bar | |||||

| 150 | 300 | 600 | 900 | 1500 | 2500 | |

| -29 to 38 | 18.4 | 48.0 | 96.0 | 144.1 | 240.1 | 400.1 |

| 50 | 18.2 | 47.5 | 94.9 | 142.4 | 237.3 | 395.6 |

| 100 | 17.4 | 45.3 | 90.7 | 136.0 | 226.7 | 377.8 |

| 150 | 15.8 | 43.9 | 87.9 | 131.8 | 219.7 | 366.1 |

| 200 | 13.8 | 42.5 | 85.1 | 127.6 | 212.7 | 354.4 |

| 250 | 12.1 | 40.8 | 81.6 | 122.3 | 203.9 | 339.8 |

| 300 | 10.2 | 38.7 | 77.4 | 116.1 | 193.4 | 322.4 |

| 325 | 93 | 37.6 | 75.2 | 112.7 | 187.9 | 313.1 |

| 350 | 8.4 | 36.4 | 72.8 | 109.2 | 182.0 | 303.3 |

| 375 | 7.4 | 35.0 | 69.9 | 104.9 | 174.9 | 291.4 |

| 400 | 6.5 | 32.6 | 65.2 | 97.9 | 163.1 | 271.9 |

| 425 | 5.5 | 27.3 | 54.6 | 81.9 | 136.5 | 227.5 |

| 450 | 4.6 | 21.6 | 43.2 | 64.8 | 107.9 | 179.9 |

| 475 | 3.7 | 15.7 | 31.3 | 47.0 | 78.3 | 130.6 |

| 500 | 2.8 | 11.1 | 22.1 | 33.2 | 55.4 | 923 |

| 538 | 1.4 | 5.9 | 11.8 | 17.7 | 29.5 | 49.2 |

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)