Double Piston Effect Ball Valve

Double piston effect ball valve: both seats block the flow from upstream and downstream independently; thus, if one of the seats is damaged, the other seat can still work to block the flow from both sides.

The disadvantage is that the over-pressure built into the valve body cannot be relieved up or/and downstream automatically. A safety valve is needed to be installed on the DPE ball valve body to relieve the over-pressure automatically.

Double Piston Effect Ball Valves

API 6D definition: "Double Piston Effect Ball valve is a single valve with two seating surfaces, each of which, in the closed position, provides a seal against pressure from a single source, with a means of venting/bleeding the cavity between the seating surfaces. "

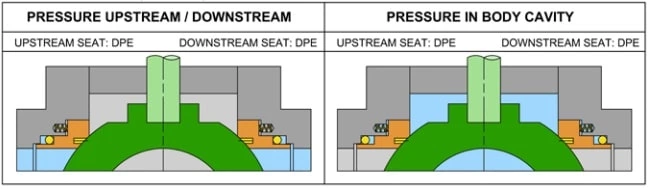

DIB ball valves are made of double piston effect seats. Each seat is to be pushed against the ball in both cases, whether pressure comes from the body cavity or from the upstream or downstream side.

Double Piston Effect Seat*Double Piston Effect Seat:DIB-1

DIB-1 trunnion ball valves are combined with two piston seats. If one seat is broken, the other seat can still cut off the flow from both ends. A ball valve with two DPE seats cannot perform cavity relief. For this reason, in liquid services, the use of a relief valve to relieve pressure into the atmosphere is recommended.

Double Isolation & Bleed (DIB-1): Both Seats are DPE Seats

DIB-2 (DPE-SPE Seats)

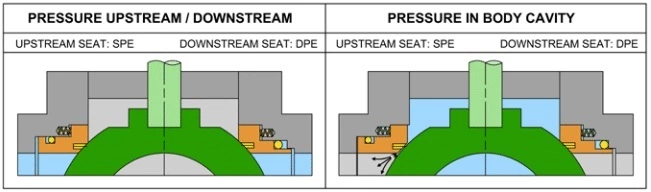

The upstream SPE seat ensures self-relieving capability, while the downstream DPE seat provides a double barrier in the event that the upstream seat is damaged. This configuration involves a preferred direction of installation with the SPE seat facing upstream. With SPE-DPE configurations, cavity relief always takes place through the SPE seat.

DIB-2, One seat is DPE, the other seat is single piston effect.

The double piston effect ball valve is designed for trunnion mounted ball valve only. There is no piston effect in the floating valve design. Seats are usually locked into their respective pockets, so the ball is floating against one or other seat upon flow or pressure changes.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)