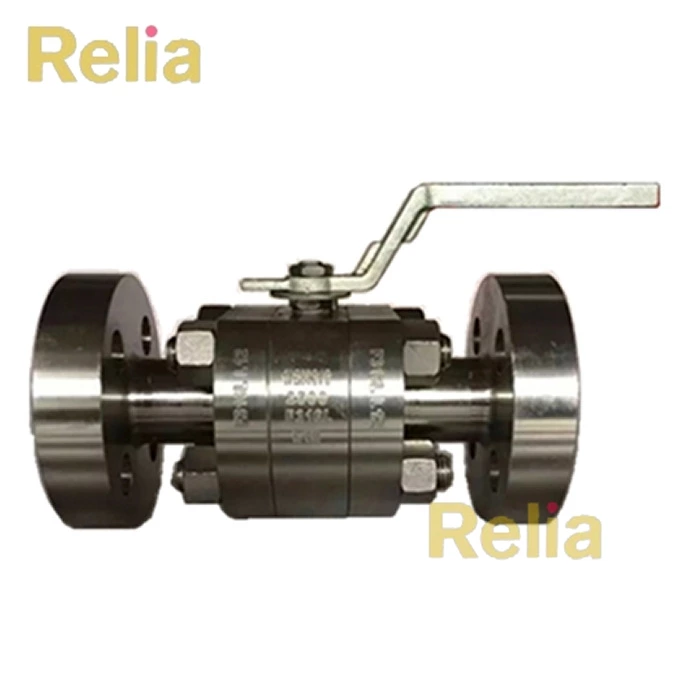

A182 F316 Ball Valve

A182 F316 Ball Valve is made of ASTM A182 F316 that is a forging material specification for improved corrosion resistance.The ball valve body and trim are all made of ASTM A182 F316.

ASTM A182 F316 Ball Valve specifications

| Part Name | Body/Bonnet | Bolting | Stem | Ball | Seat | Spring |

| Material | ASTM A182 F316 | A193 B8M/A194 8M | ASTM A182 F316 | ASTM A182 F316 | RPTFE, Devlon, PEEK, etc. | Inconel 725 |

ASTM A182 F316 Ball Valve Test Pressure

| Test Type | Test Fluid | Test Pressure (bar) | |||||

| Class 150 | Class 300 | Class 600 | Class 900 | Class 1500 | Class 2500 | ||

| Shell Test | Water | 28.5 | 74.4 | 148.95 | 223.35 | 372.3 | 620.55 |

| High Pressure Seat Test | Water | 20.9 | 54.56 | 109.23 | 163.79 | 273.02 | 455.07 |

| Low Pressure Seat Test | Air | 6 | 6 | 6 | 6 | 6 | 6 |

ASTM A182 F316 Chemical Requirement

| Grade | UNS Designation | C | Mn | P | S | Si | Ni | Cr | Mo | Others |

| F 304 | S30400 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | N 0.10 | |

| F 304H | S30409 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | ||

| F 304L | S30403 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-13.0 | 18.0-20.0 | N 0.10 | |

| F 304N | S30451 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-10.5 | 18.0-20.0 | N 0.10-0.16 | |

| F 304LN | S30453 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-10.5 | 18.0-20.0 | N 0.10-0.16 | |

| F 309H | S30909 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 12.0-15.0 | 22.0-24.0 | ||

| F 310 | S31000 | 0.25 | 2.00 | 0.045 | 0.030 | 1.00 | 19.0-22.0 | 24.0-26.0 | ||

| F 310H | S31009 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 19.0-22.0 | 24.0-26.0 | ||

| F 310MOLN | S31050 | 0.030 | 2.00 | 0.030 | 0.015 | 0.40 | 21.0-23.0 | 24.0-26.0 | 2.00-3.00 | N 0.10-0.16 |

| F 316 | S31600 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | N 0.10 |

| F 316HI | S31609 | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | |

| F 316L | S31603 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-15.0 | 16.0-18.0 | 2.00-3.00 | N 0.10 |

A All values are maximum unless otherwise stated. Where ellipses (...) appear in this table, there is no requirement and analysis for the element need not be determined or reported.

Tensile and Hardness Requirements A

| Grade | Tensile Strength, min, ksi [MPa] |

Yield Strength, min, ksi [MPa]B |

Elongation in 2 in. [50 mm] or 4D, min, % |

Reduction of Area, min, % |

Brinell Hardness Number, HBW, unless otherwise indicated |

| F316 | 75 [515]C | 30 [205] | 30 | 50 | . . . |

A Where ellipses appear in this table, there is no requirement and the test for the value need neither be performed nor a value reported.

B Determined by the 0.2 % offset method. For ferritic steels only, the 0.5 % extension-under-load method may also be used. C For sections over 5 in. [130 mm] in thickness, the minimum tensile strength shall be 70 ksi [485 MPa].

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)